Elaborate

When a customer presents us an inspection job, we consider the whole concept. First of all, is the job feasible? Will the benefits of implementing and introducing an inspection system be justified in terms of costs? Basically, does it make sense to introduce this type of technology at all?

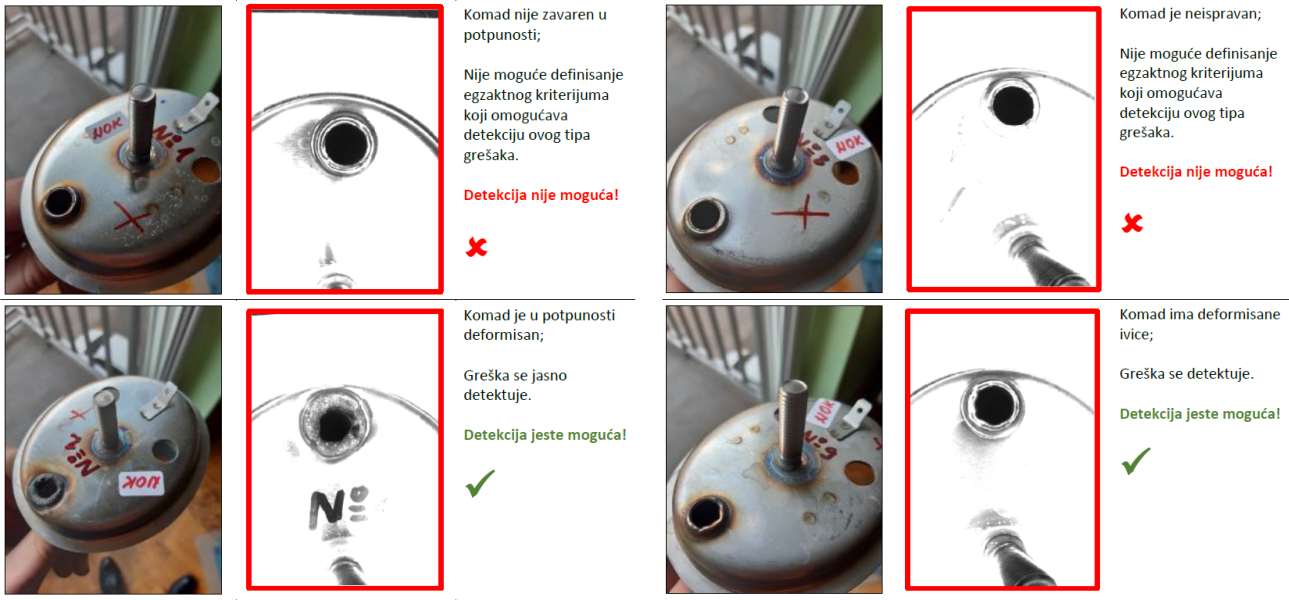

If the work is estimate to be feasible, we look for samples for inspection, as well as pictures of machine parts, processes or installations. It is very important to have the right samples. In that sense, we get good, bad and samples with marginal defects. Samples with marginal defects are the most difficult for inspection, because we can accept them as good or bad. These samples/ defects determine the sensitivity of the system.

After that, we start preparing the elaborate. The elaborate includes testing the inspection system with collected samples using the most modern sensors (hardware) and software tools.

After the research, we give a proposal for the realization of the job, which is very often based on previous experiences on similar projects.

At the end of the study, we provide a final report on the feasibility of the system. The elaborate is not an additional cost for the project, because it is part of the development. Preliminary system testing removes the risk of the project and provides a better insight into the limitations of the system as well as the benefits of the application.